To sterilize fabrics and wrapped instruments, mechanical air removal from the chamber is important. This ensures uniform penetration of steam. A high performance and efficient vacuum pump takes care of this by means of automatic pulsation prior to treatment. This ensures removal of all air pockets from the load. The post vacuum treatment ensures vacuum drying of the load before unloading.

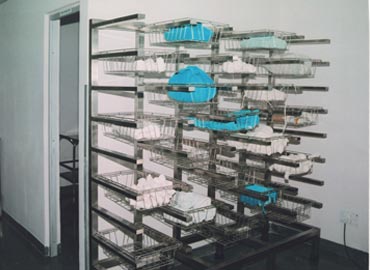

The system is equipped with various programs, which offers full range of cycle combinations to cater to all your needs. Six preprograms for instant selection are provided.

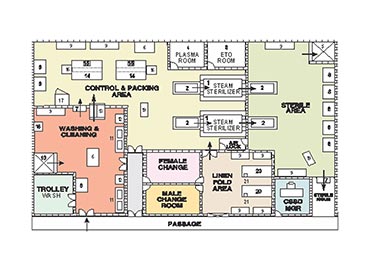

The chamber is a critical part of a Steam Sterilizer. It is a critical part due to the temperature and pressure variations, which it has to withstand. Machinfabrik offers you a chamber designed as per ASME section VIII and with documentation including weld qualification, radiography testing, and surface finish profile, material testing & hydro-testing. The sterilization chambers are provided with a sloping bottom to ensure complete condensate removal from the system. The chamber is equipped with a Jacket, improving temperature uniformity inside the chamber & also provides strength to the chamber.